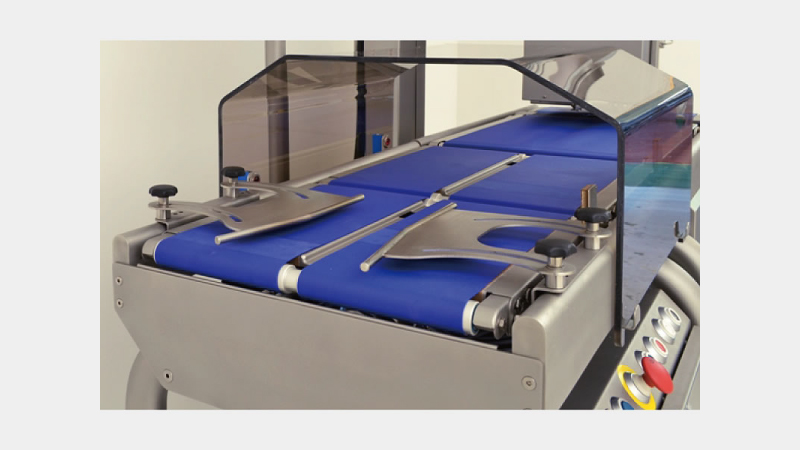

Barcodes – 21 different symbologies at your fingertips, including 2D & QR.Constant Torque Conveyor Drive System – packages maintain constant speed throughout whole machine.The Global 5 and 10 Largest Players: Market Share by Dynamic Weigh Price Labeller Revenue in 2021 Figure 22. Global Market Dynamic Weigh Price Labeller Average Price (US/Unit) of Key Manufacturers in 2021 Figure 21. Connectivity – The heart of a fully implemented WPL installation opens the world of Remote Trouble Shooting & Maintenance, Central Product Maintenance. Dynamic Weigh Price Labeller Market Share by Company Type (Tier 1, Tier 2 and Tier 3): 2017 VS 2021 Figure 20.Quick release conveyors and open frame design for easy cleaning. Maintainability – Quick change wear items Belts, Print Heads, Actuators.Modularity – Allows upgrades & expansions to existing equipment without losing initial investments. Manufacturer: Marel Marel / AEW delford, 2008, Stainless weigh price labeler, min weigh t 1.5kg - max weigh t 20kg, scale interval 1/2g, Max tare weigh t -1Kg, overall length 2750mm, belt width 200mm, weigh platform 200mm x 240mm, with.Robust - Stainless steel construction to handle the harsh production environments of the protein industry.Top & Bottom labeling, Label sizes from 1.5” x 1.5” to 4” x 5”, True Type Fonts, Graphics.Versatility – One machine for all your labeling needs.

Speed – Throughput up to 150 packages per minute.fast handing of the weighing process label printing and archiving weighing data records. MAPModified Atmosphere Packaging, vacuum packaging, fresh-keeping packaging, food cling wrap. WYSIWYG label design application integrated with the Ossid control system for quick and simple label creation and editing capabilities. weigh price labeller is ideal for tray or packs of meat, vegetable, products. New “Smart Print” technology allows for 20-40% throughput by eliminating the need to retract label stock. The user interface was redesigned with the user in mind. Ossid’s Next Generation Weigh Price Labeler (WPL) incorporates the latest NTEP approved load cell and measurement electronic technology.

Weigh price labeller software#

The hybrid control system combines machine controls and system software into one processing unit, allowing for faster weighing, processing, and labeling times, which means more packages per minute. The NextGen WPL features all new control system, designed with the latest technology. Rest assured, Ossid will be ahead of the curve, quickly responding to the ever-changing North American marketplace. Ossid’s Next Generation Weigh Price Labeler (WPL) is domestically designed & built. Easy operation with soft keys for basic price, tare and date with self-explanatory. Various models with speeds range from 70 to 170 packages per minute to suit your production line. Versatile setup with different label orientations i.e. The open frame design allows for ease of maintenance. All-in-one weighing, pricing, labeling in one machine with controls of up to 6 labelers.

Modularized assembly allows for short lead and delivery time. The Ossid NextGen Weigh Price Labeler (WPL) has been completely redesigned from the ground up.

0 kommentar(er)

0 kommentar(er)